Coexpair and Coexpair dynamics develop and market their own Floware™ and Maestro™ software suite, fully compatible with the control and monitoring of AFP and (SQ)RTM composite manufacturing processes and adaptable to the requirements of each customer.

Single Workstation SCADA

Floware™ is machine-specific monitoring, control, and data acquisition software. It records critical data from each piece of equipment, such as

temperatures, pressures, speed, head positionning, alarms, events, operator notes, and more.

Aggregated data from Multiple Workstations

Maestro™ is a centralized system that aggregates data collected from each Floware™-equipped machine, enabling added value. It enables, for example, live

and post-production process monitoring, automatic generation of reports comparing manufacturing cycles and tolerances, and the creation of statistics

to guide manufacturing and organize predictive maintenance. It can also be connected to your preferred Enterprise Resource Planning (ERP) software.

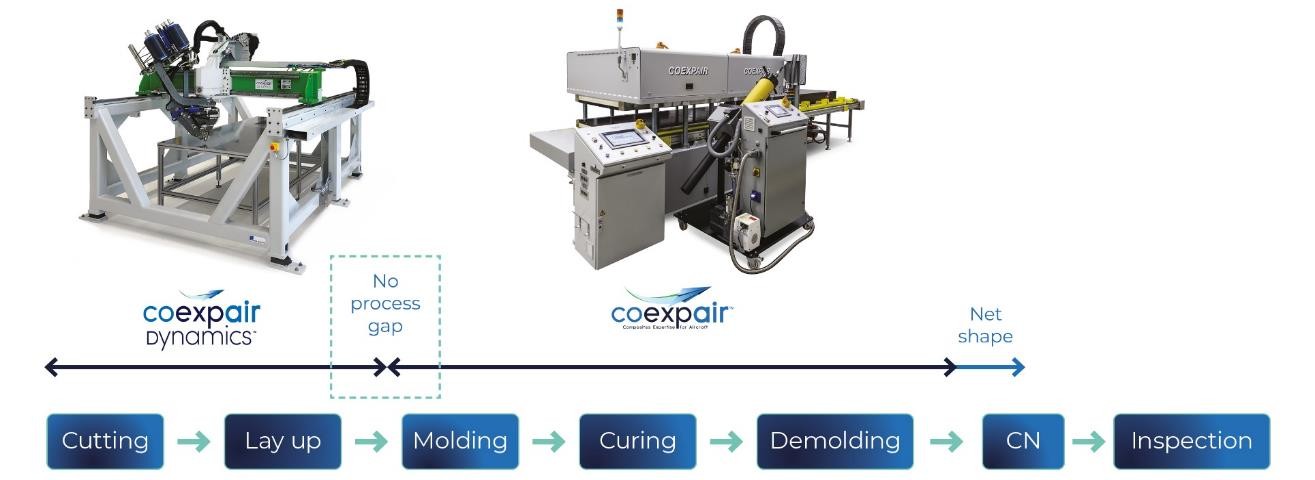

From AFP to RTM/SQRTM

To improve productivity, the same software suite, consisting of Floware™ and Maestro™, allows you to manage the entire

composite manufacturing workshop, with a single screen for all your activities and complete traceability. For example, Coexpair Dynamics' automated fiber

placement machines are equipped with Floware™, in the same way that Floware™ is used with the workstations and injectors supplied by Coexpair for the

closed-mold polymerization of composites using RTM/SQRTM manufacturing processes.