3-days AFP/ (SQ)RTM training for Engineers & Technicians

In collaboration with Coexpair, Coexpair Dynamics proposes a 3-days general introduction to AFP & (SQ)RTM for Aerospace.

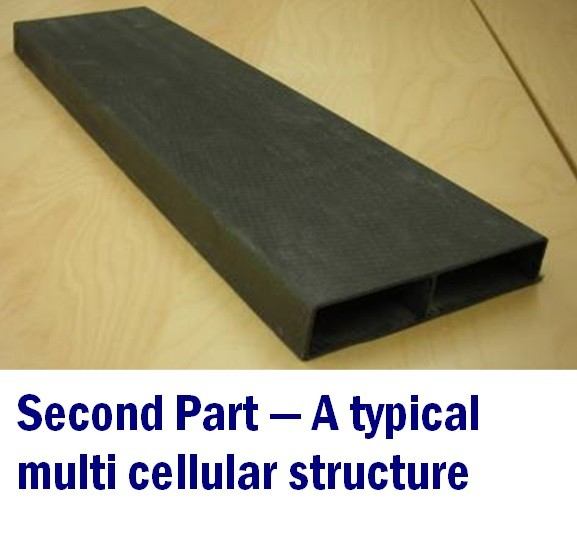

It covers the process, the design, the materials and the equipment used. 2 parts are fabricated by the participants to illustrate the theory &

provide hands-on learning. Following attendants expertise and interest the program is tuned. The discovery of the AFP & SQRTM process by the manufacturing of one part is proposed as an option.

Program

- 01 - Introduction to aerospace composite processes. AFP / (SQ)RTM state of the art.

- 02 – Illustrated presentation of the AFP / (SQ)RTM processes.

- 03 - Practice in the shop: AFP lay up. «Bulk factor » measurement. Mould preparation.

- 04 - Aerospace resin with their respective application (epoxy, BMI,etc…). Links between resin chemistry, mechanical properties and process.

- 05 - Aerospace reinforcement fibers (glass, aramide, carbon). Commercial denomination, architecture, mechanical performances & applications. Link

between fiber surface & resin chemistry. - 06 – Automated Fiber Placement. Presentation of different equipment. Pro & Cons. Risks and safety.

- 07 – Injection system. Presentation of different equipment (pressure controlled, flow controlled, pail un-loader, pressure pot). Pro & Cons. Risks and safety.

- 08 - Preforms for SQ(RTM): UD, fabrics, braids. Usage and performances.

- 09 - Practice in the shop: First part: process understanding & spring-in effect illustration

- 10 - Lay-out of a typical AFP/SQ(RTM) shop, from tow to net shape part.

- 11 - Practice in the shop: Part manufacturing.

- 12 – Introduction to composite design & recommendations for AFP/SQ(RTM) part design.

Location

This training is given at Coexpair in Belgium using Coexpair industrial equipment. Typical group size is 4-6 people.