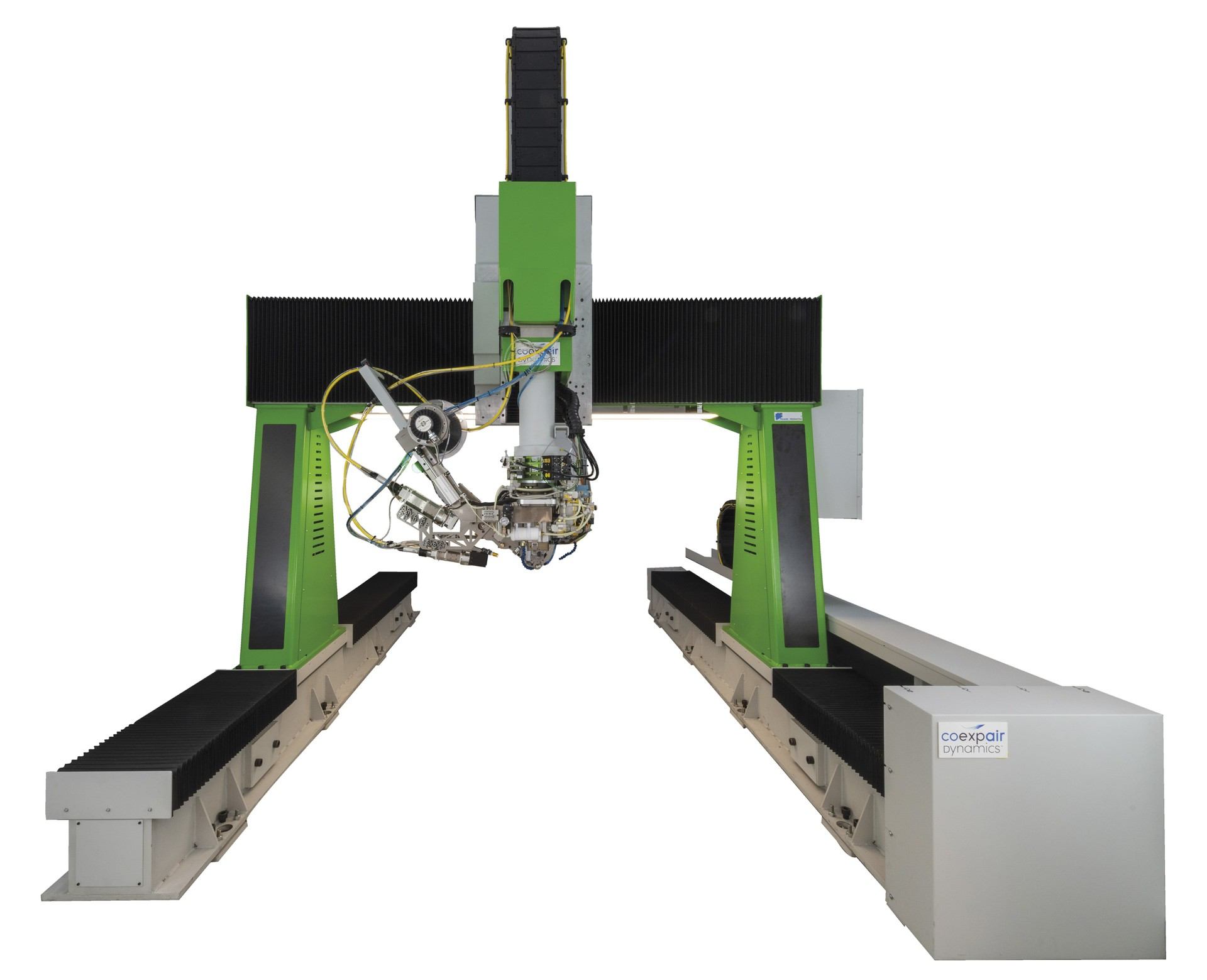

Coexpair Dynamics offers custom-made Gantry Automated Fiber Placement machines. For the past 30 years, our robust design has been continuously improved to meet the demands of production environments. With a spool positioned close to the nip point, friction is minimized, ensuring superior accuracy and smoother operation. Starting and stopping the process is effortless, requiring only four spools, making the system highly efficient.

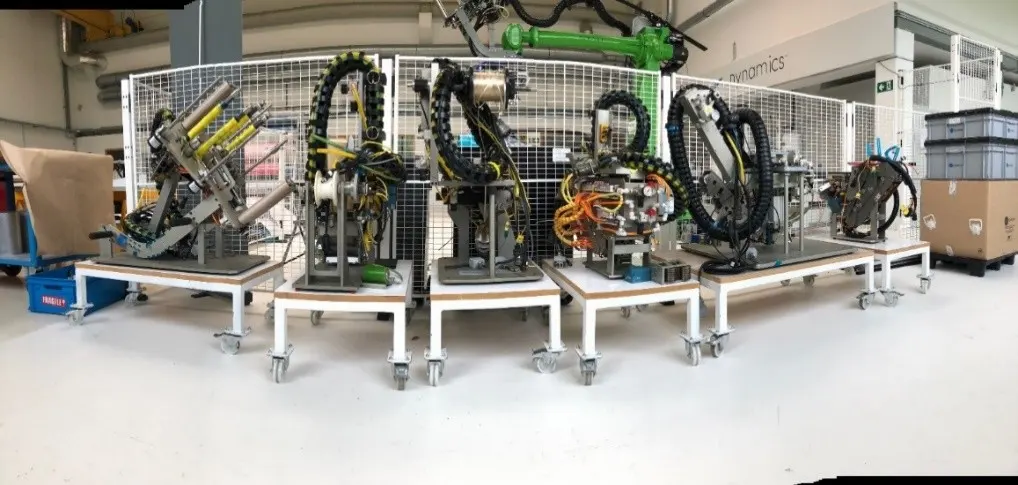

The autonomous head is easily exchangeable, allowing for quick adaptability to different requirements. Laser heating control, based on TP in-situ consolidation, ensures precision and reliability. The dual laser system, targeting both the incoming material and the substrate is perfectly suited for complex geometries and optimized TP in-situ consolidation.

With a compact 1-inch width, the head is designed for intricate structures, offering flexibility in manufacturing. Siemens-based technology, widely recognized in the aeronautics industry, ensures a reliable and standardized approach. Built with the latest generation CNC, our solution is tailored for

Industry 4.0, embracing digital advancements for enhanced performance.

Designed as a flexible and adaptable solution, it can be customized for specific applications. Unlike off-the-shelf products or closed systems, we collaborate closely with customers to develop solutions tailored to their needs. Additional support is provided through test benches and process simulations at the material level, utilizing the same hardware for seamless integration and optimization.

For detailed technical specifications of all our machines, please refer to the catalog attached below.