Coexpair Dynamics extends the offer of Coexpair in the development of composite applications and supply of production equipment. For nearly 20 years, Coexpair has been developing and supplies now out of autoclave molding and curing industrial solutions for aerospace composite production. With fiber deposition automation, Coexpair Dynamics and Coexpair propose custom integrated solutions from tow to net-shape part.

The strategy of Coexpair Dynamics is based on the original business model of Coexpair. It offers services to support its customers in the collaborative development of new applications. This includes the manufacture of demonstrators and first parts prototypes in its Belgian facility (no serial production). Once the development is complete, Coexpair Dynamics extends its offer to the design and assembly of automatic deposition equipment needed for part production. Services delivered by Coexpair Dynamics are engineering, including feasibility study, business case and innovative solutions; and process development, with among others new materials studies, panels manufacturing by AFP and R&D combined with AFP&RTM or SQRTM processes.

- Equipment Architecture definition in collaboration with customer

- Aerospace Engineering Services:

- Studies (lay-up feasibility and analysis, risk assessment …),

- Business case (RC/NRC analysis, manufacturing risk analysis, serial cost estimation,…)

- Materials and process studies

- Process Set-up to First Part Qualification:

- Process optimization,

- Panels/tubes manufacturing for coupons testing,

- Manufacturing of sub-components or demonstrators using (SQ)RTM.

- Combination of automated fiber placement (AFP) with (SQ)RTM

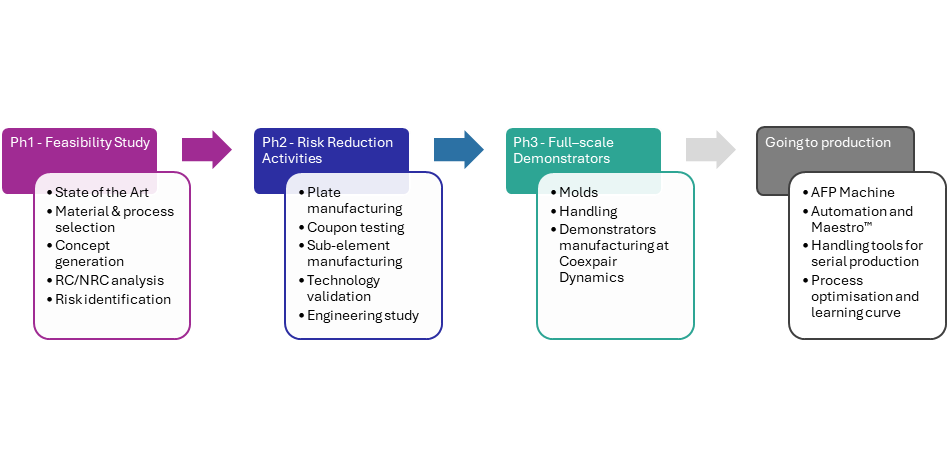

Development program is made of 3 Phases, from concept initiation to full-scale demonstration with the objective of being ready to ramp up to high-rate serial production with an innovative cost-saving solution. The purpose is not only to provide customer with an industrialization study but

also to define and to deliver innovative industrial equipment dedicated to serial production.

To answer completely to customer needs, Coexpair Dynamics foresees a complete tailored made solution scheduled in 3 phases, e.g.:

- Phase 1 is feasibility study.

- Phase 2 would be the derisking activities including sub-element demonstrator.

- Phase 3 would be full-scale demonstrator, phase 3 ends with final ramp up in high-rate serial production.

After these 3 phases development, Coexpair Dynamics could define and deliver manufacturing equipment for serial AFP production.

Typical 3 phases development plan to go in serial production: