To support Belgium’s strategic positioning in the European FCAS program, the BestCMR project aims to advance next-generation composite manufacturing for combat aircraft. Led by Coexpair, a strategic Airbus supplier, BestCMR unites Belgian high-tech SMEs to showcase their expertise in net-shape aerostructures and aeroengine parts. The initiative strengthens Belgium’s industrial base and opens new defence sector opportunities.

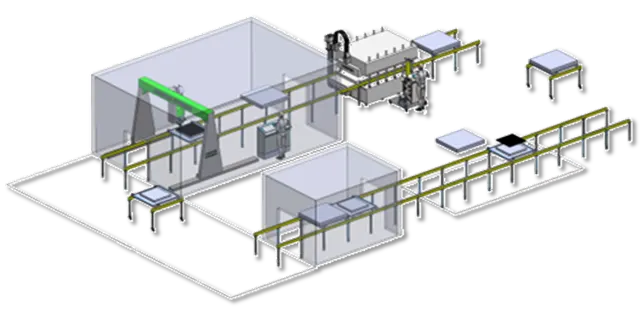

Aligned with Theme 4 of the NGCAT framework, BestCMR builds on achievements like Coexpair’s reshoring of A320 spoiler production, which cut costs by 30% and created 170 jobs. The project’s goal is to develop a fully automated, high-efficiency composite manufacturing line. It integrates state-of-the-art equipment and digital technologies, including digital twins and AI-driven process control, enabling up to 30% cost savings and 80–90% energy reductions.

Partners contribute complementary expertise: Balliu (automation), Coexpair Dynamics (fibre placement), Pégard Productis (precision machining), Argon and Optrion (inspection), GDTech and Cenaero (simulation), with integration into Airbus-CTC’s ecosystem. The result will be a fully integrated composite shop, from material arrival to final inspection.

Expected outcomes include validated manufacturing models, digital simulations, integrated workflows, stakeholder workshops and peer-reviewed publications. BestCMR supports European defence autonomy, creates high-value jobs, and positions Belgium as a centre of excellence in composite innovation, with applications across aerospace, space and automotive sectors.

Project

BestCMR – Belgium Strategic

Composite Manufacturing Resource

Project overview

7 partners – €4.950 million budget

Program

Project funded by the Belgian

Royal Higher Institute for Defense (RHID)

Project Website

(ongoing)