The selection of material and the set-up of process parameters are the heart of our engineering services. Manufacturing of flat panels for coupons is a common task. More complex tools are also used to validate the mechanical performances at higher level (sub-element level).

Our shop is the right place for our customers to manufacture their first full scale parts using RTM state-of-the-art industrial equipment (mold, injection system and workstation). Customers can use Coexpair shop equipment to manufacture plates for coupon manufacturing and material characterization with

existing molds. Demonstrators can be also manufactured in our presses with size up to 4X1.3m

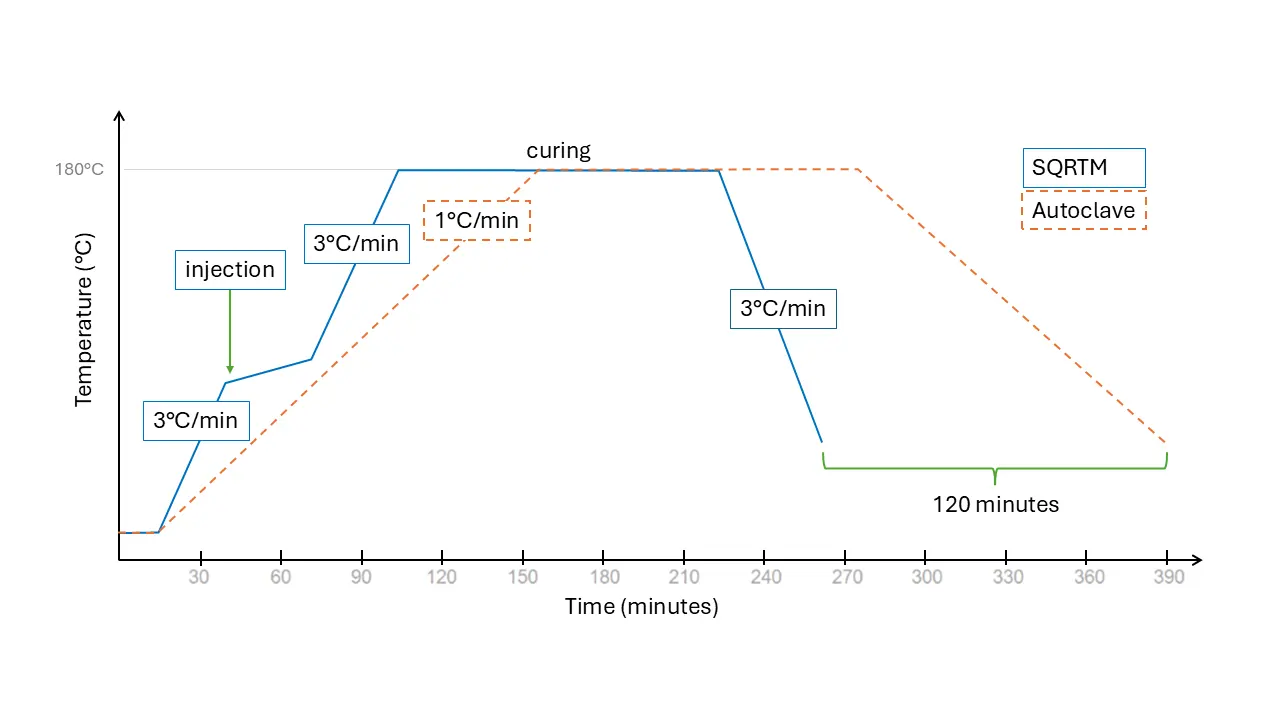

Coexpair specializes in Resin Transfer Molding (RTM) and Same-Qualified Resin Transfer Molding (SQRTM), advanced closed-mold processes that deliver high-performance composite parts with exceptional precision. RTM involves injecting liquid resin into a closed mold containing a dry fiber preform, producing components with excellent surface finish on both sides, tight dimensional tolerances, and high fiber volume fractions for optimal strength-to-weight ratios. SQRTM looks like RTM by utilizing pre-impregnated (prepreg) layups and combining resin injection with compression, allowing for greater control over resin flow and part consolidation than autoclave. These technologies are achieving net-shape, aerospace-grade components with reduced voids and faster cycle times.

These processes offer significant advantages for complex aerostructure manufacturing, including the ability to create intricate geometries and integrated features, which can lead to reduced part count and assembly costs.

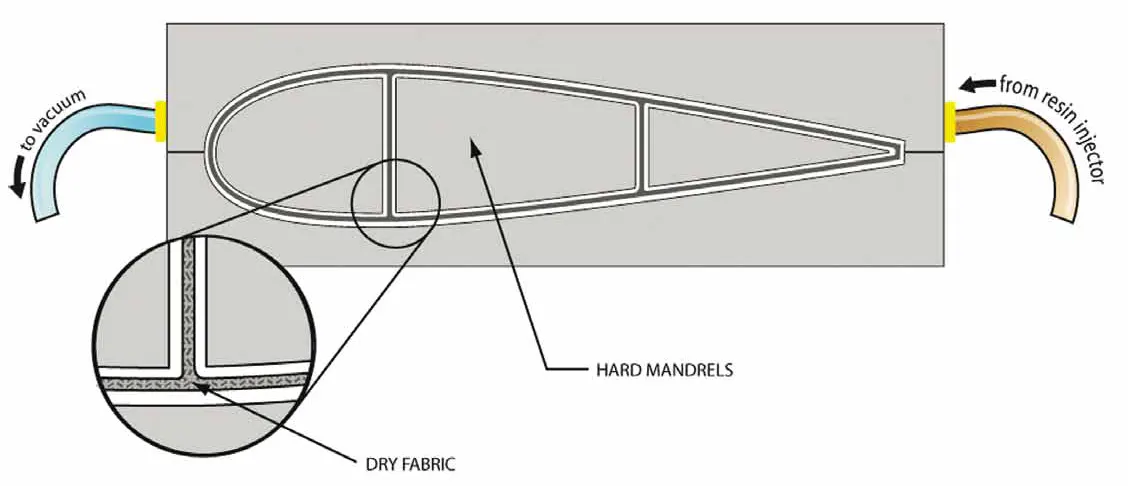

RTM (Resin Transfer Molding):

- Uses dry reinforcement to make preform

- Tooling is generally steel or aluminum, on all surfaces

- Resin is thoroughly degassed and vacuum is drawn on tool

- Low viscosity RTM resin, <500 cps, infuses entire preform

- Resin pressure maintained at 7 to 8 bars during cure

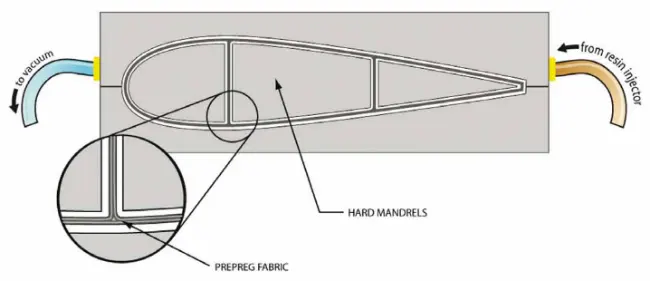

SQRTM (Same Qualified Resin Transfer Molding):

Radius Engineering and Coexpair have created this innovative process for out-of-autoclave manufacturing:

- Allows use of program-specific prepreg (“same qualified”), including

toughened systems such as Hexply 8552 ®, Hexply M21 ®, Cycom 977 ®, Cycom 5250-4 ® BMI, Toray 3900-2 ® (BMS 8-276) - Fabrics or UD tapes previously laid by hand or using automatic devices (AFP, ATL)

- Tooling is aluminum, steel or Invar

- High vacuum is drawn on tool

- As tool is heated, small quantity of prepreg resin is injected into tool to fill tool cavity around edges of part and maintaining resin hydrostatic pressure at 8 - 9 Bar during cure

Net Shape solutions, manufactured in matched mold with accurate process control are the key for repeatable composite production.