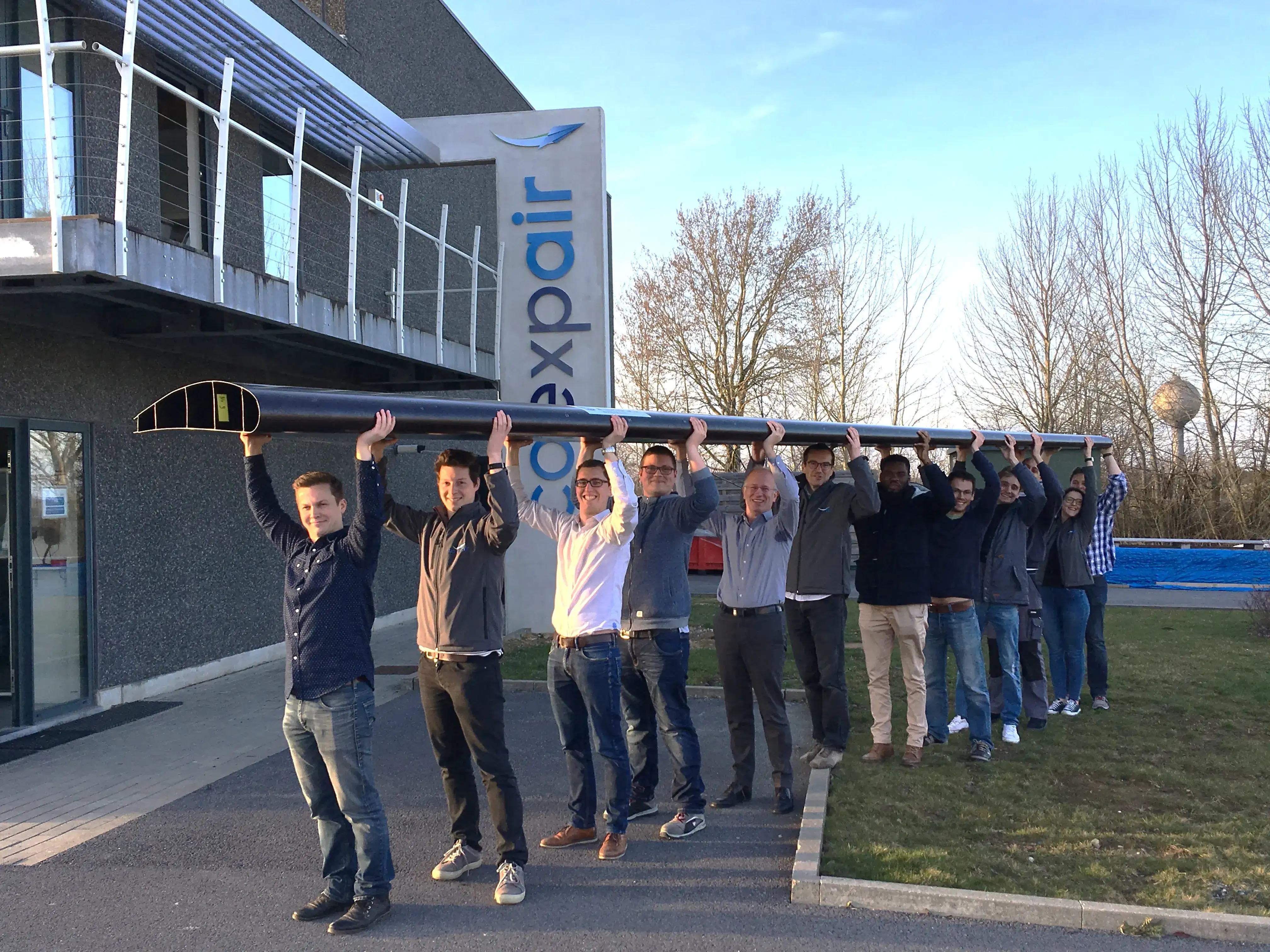

Coexpair in Europe and its partner Radius Engineering in USA have supported many OEM and Tiers Ones in the development of innovative and challenging composites aerostructures.

Coexpair proposes to support your company all along the development program: from concept initiation to full-scale demonstration. Coexpair’s goal is not only to provide you with an industrialization study in our but also to define and deliver exclusive industrial equipment dedicated to serial production.

Our Application Development Centers can support you all along development program. We are innovation hubs :

- Expertise - since 1986 (Radius USA) & 2006 (Coexpair EU)

- Agility - 30 peoples per company (2x) + services network.

- Skill - ~15 engineers per company (2x) + consultants.

- Equipment - unique R&D equipment both in USA & EU.

100% Focused on RTM/SQRTM for aerospace.

That delivers Cost Reductions, based on:

- Innovative part architecture

- Efficient processes prone to automation

- Production equipment & tool of premium quality

- Large supply chain to produce equipment & tool

- Transfer of technology & training

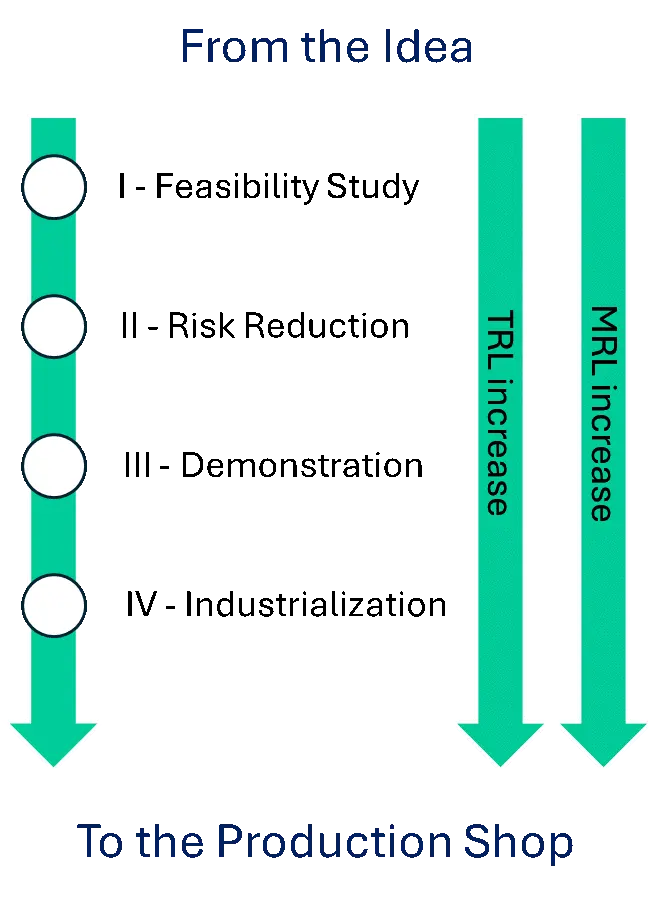

From Idea to high-rate composite production shop

Phase I – Feasibility Study

- Architecture, Materials and Process, FEA, concepts

- Cost Analysis (RC/NRC) : business case

- Risks Analysis & Mitigation Plan

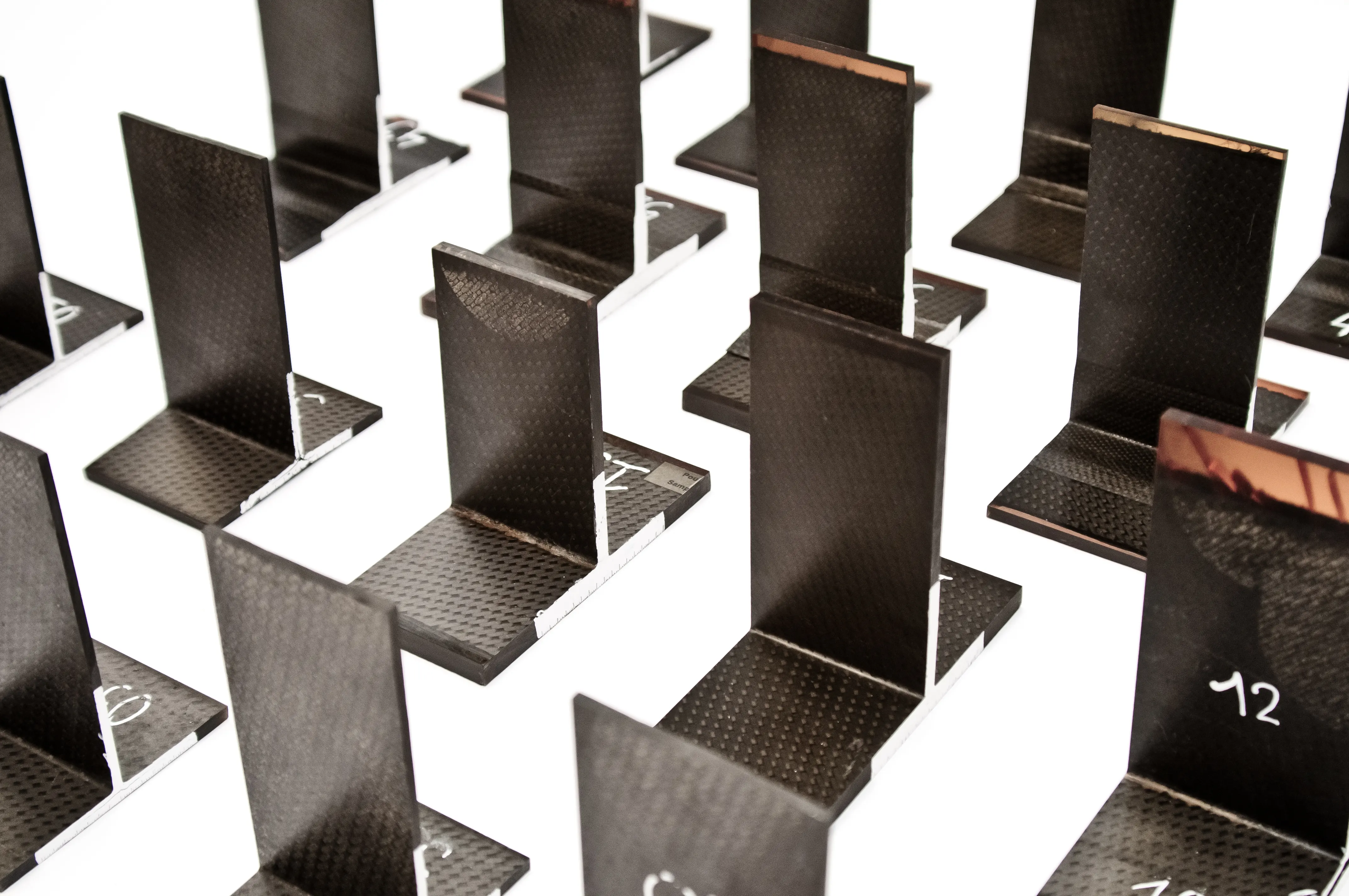

Phase II – Risk Reduction

- Coupons, sub-element, tests

- Detailled design & Analysis, M&P

- Full scale mold design

Phase III – Demonstration

- Full scale mold fab

- Full scale demo fab

- Full scale test

Phase IV – Industrialization

- Production Molds

- Production Presses & Injectors

- Training & Support

Contact us to bring your idea into a succesfull composite shop.