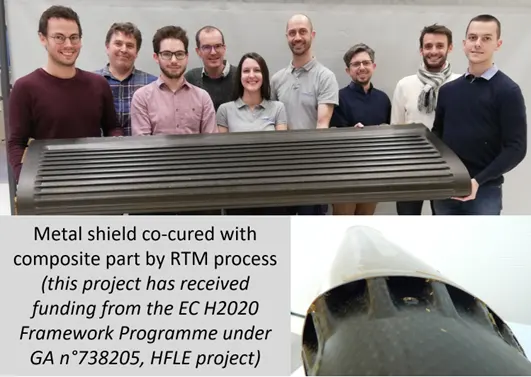

The HFLE project coordinated by Coexpair within the Clean

Sky 2 programme, tackled the challenge of cost-effective composite

manufacturing for aeronautics. As aircraft demand surges and weight reduction remains critical for fuel efficiency and emissions reduction, traditional autoclave-based composite processes are increasingly unsustainable due to high costs and low production rates. HFLE addressed this by developing an innovative, automated Resin Transfer Moulding (RTM) process tailored to complex structures like the Horizontal Tail Plane (HTP) leading edge.

Coexpair, a Belgian SME specialized in out-of-autoclave composites, led a high-level consortium to design and validate smart, low-cost tooling enabling RTM of a full-scale HTP demonstrator. Major achievements included a novel eco-designed mould using aluminium for energy savings,

automation of key RTM steps, and integration of sustainable materials and

practices. The resulting composite parts met strict aerospace requirements with minimal scrap and porosity, achieving TRL5+ and setting the stage for TRL6.

Key benefits include reduced manufacturing costs, energy consumption, and environmental impact, while maintaining structural integrity and aerodynamic performance. The project also demonstrated the feasibility of re-shoring production to Europe thanks to competitive, high-value manufacturing. HFLE's success supports broader adoption of RTM in aerostructures—paving the way for future sustainable, high-performance aircraft designs. Through HFLE, Coexpair has positioned itself as a European leader in RTM technology, now equipping major aerospace players

like Spirit AeroSystems.

Project

HFLE – Hybrid Fixed Leading Edge

Project overview

4 partners – €1.3 million budget

Program

Project funded by the European Union’s program Horizon 2020 under grant agreement No. 738205

Project Website

https://cordis.europa.eu