Coordinated by Coexpair, COMP4++ aims to revolutionize the manufacturing of high-value composite parts – especially in the aeronautics

sector – by integrating intelligent digital tools into production systems. As

composite manufacturing becomes more advanced, with larger, more integrated parts produced to tight tolerances, the need for real-time process control and predictive quality assurance becomes critical.

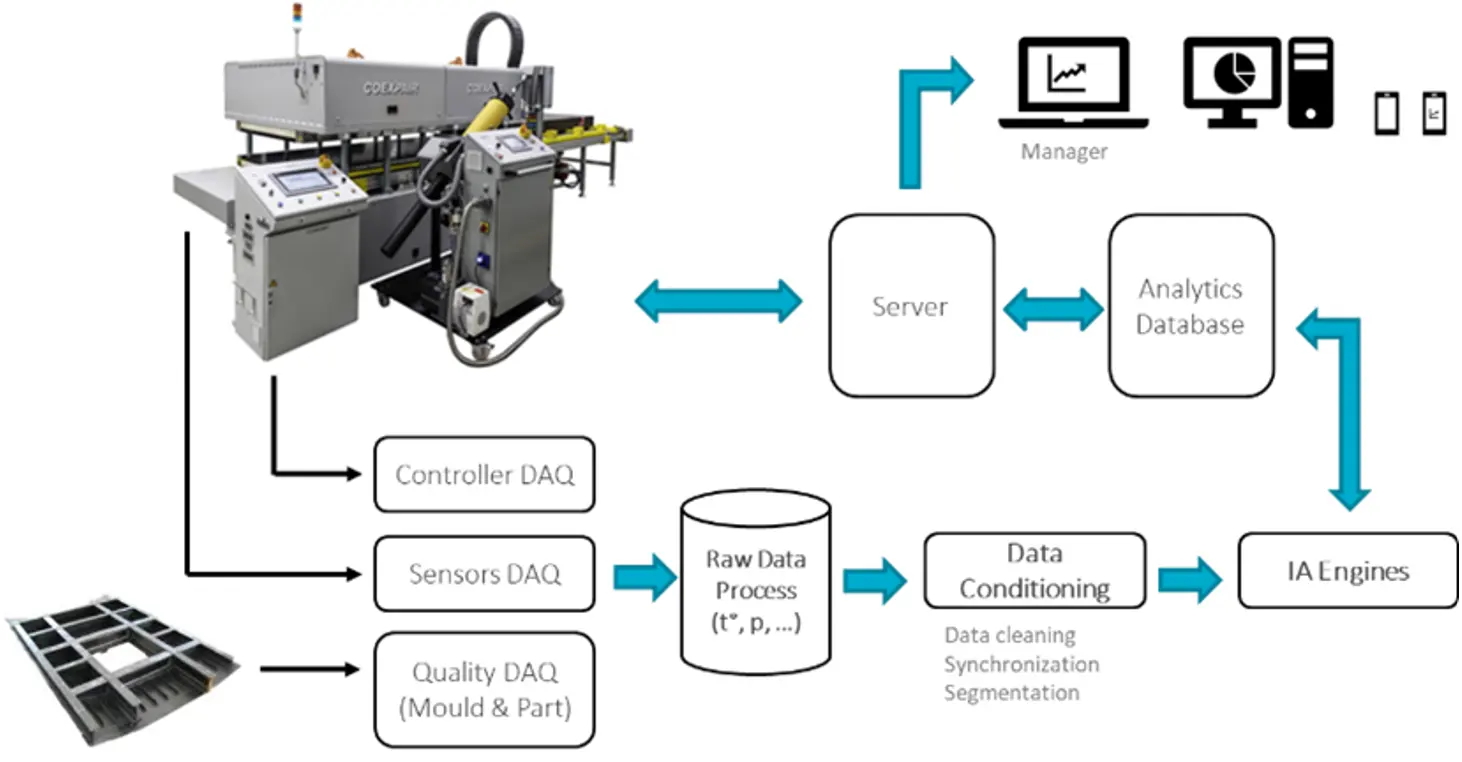

Coexpair is enhancing its production RTM equipment with

Computer-Assisted Intelligence (CAI) to anticipate anomalies during

manufacturing. This innovation targets a significant improvement in part

conformity rates by leveraging real-time data from equipment (presses,

injectors, molds) and integrating it into a centralized, intelligent monitoring

and decision-making system.

Unlike current manual and fragmented data analysis methods, COMP4++ seeks to develop a standardized, scalable digital solution tailored to the specific needs of composite manufacturing. The project is aligned with the aerospace industry's digital transformation strategies, such as Airbus’s DDMS initiative, and has already attracted interest from major OEMs

and Tier-1 suppliers.

Coexpair’s leadership is supported by partners Sobelcomp and MTU, as well as academic institutions UMons and ULiège, who contribute expertise in AI, database management, and material characterization. Together, they aim to define a new “4.0” standard for RTM equipment – combining software, data servers, and services – to boost competitiveness, quality and traceability across the aerospace composite supply chain.

Project

COMP4++ – Composites 4++

Project overview

5 partners – €2.9 million budget

Program

Project funded by the Walloon region

Project Website

(ongoing)