As a key partner in the AIRPOXY project, Coexpair plays a

pivotal role in advancing the manufacturing of next-generation composite

materials for the aeronautics sector.

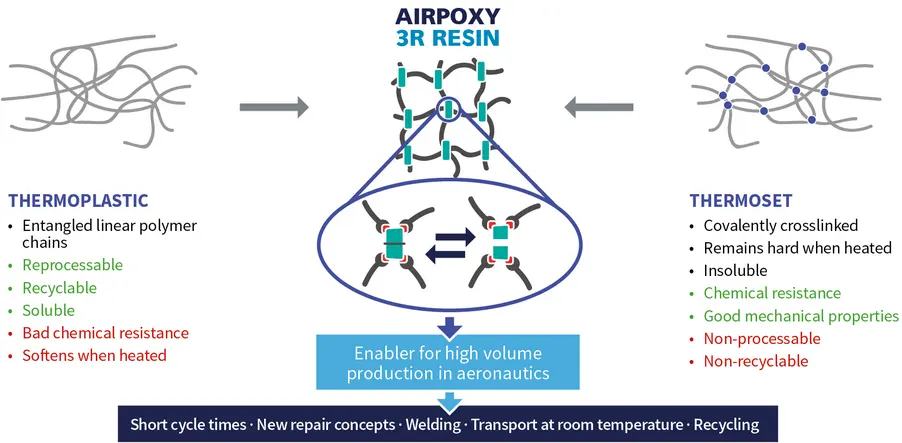

AIRPOXY aims to significantly reduce production and maintenance costs of composite parts by introducing a novel family of reprocessable, repairable, and recyclable thermoset resins – developed and patented by project coordinator CIDETEC. These innovative resins retain the high-performance characteristics of conventional thermosets while offering unprecedented sustainability and lifecycle benefits.

Within this ambitious initiative, Coexpair contributes its expertise by optimizing and adapting the Same Qualified Resin Transfer Molding (SQRTM) process to accommodate the new 3R resin system. This adaptation is critical for the efficient fabrication of structural composite parts, ensuring compatibility with existing aerospace manufacturing standards. Additionally, Coexpair is actively involved in defining specialized mechanical tests tailored to the stringent requirements of the aeronautical industry. Through its contributions, Coexpair supports the project's goal of transitioning the technology from proof of concept (TRL3) to industrial validation (TRL5), ultimately enabling faster processing times, reduced bonding and maintenance costs and enhanced competitiveness and

sustainability in European aerospace manufacturing.

Project

AIRPOXY – Thermoformable,

repairable and bondable smart epoxy-based composites for aero structures

Project overview

11 partners – €6.5 million budget

Program

Project funded by the

European Union’s program Horizon 2020 under grant agreement N° 769274

Project Website

www.airpoxy.eu