As a key partner in the EU-funded MAT4RAIL project

coordinated by CIDETEC, Coexpair brings advanced expertise from the

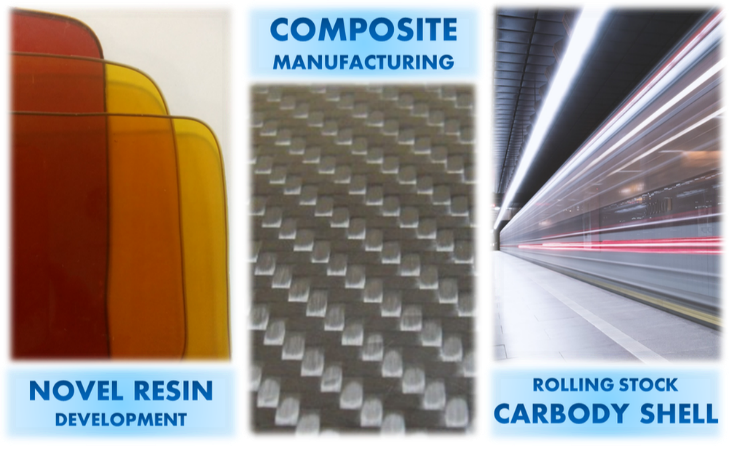

aeronautical sector to support the development of next-generation composite materials for the railway industry. The project addresses the need for lighter, more energy-efficient, and modular train designs to enhance competitiveness and sustainability in Europe’s rail sector. A major challenge is that current structural composites do not meet the Fire, Smoke & Toxicity (FST) standards required for railway applications. MAT4RAIL aims to overcome this by developing innovative Fibre Reinforced Polymers and modular interior solutions.

Coexpair leads a WP focusing on the design and manufacturing of lightweight train door leaves with improved acoustic and thermal performance. Leveraging its experience in out-of-autoclave technologies and the Resin Transfer Moulding (RTM) process, Coexpair introduces cost effective, multi-material solutions and standardized analysis tools tailored to railway requirements. The company also evaluates automation strategies to streamline composite part production and reduce costs.

Building on its prior work in the IMS&CPS project, Coexpair demonstrates that low-cost, repeatable composite manufacturing is achievable for railway structures. Its contributions are central to MAT4RAIL’s goal of enabling sustainable transport solutions—reducing energy consumption through lightweight design and increasing capacity through innovative materials. Coexpair’s role exemplifies successful cross-sector technology transfer, bringing aerospace-grade innovation to the future of rail mobility.

Project

MAT4RAIL – Designing the railway of the future: Fire resistant composite materials and smart modular design

Project overview

16 partners – €3.5 million budget

Programme

Project funded by the European

Union’s program Horizon 2020 under grant agreement No. 777595

Project Website

www.mat4rail.eu